Electric Bike Motors

Recent Posts

- Best Biking Cities in the USA for Electric Bicycles June 3, 2024

- Ride1Up Portola vs Aventon Sinch.2 Electric Bicycle May 26, 2024

- What’s a Dual Battery Electric Bicycle? April 29, 2024

- E-Bikes vs. Traditional Pedal: Which is Right For You? April 17, 2024

- Electric Dirt Bikes for BEGINNERS: Getting Started April 14, 2024

What Makes a Bicycle an e-Bike? Electric Bike Motors

If you’re thinking about buying an Electric Bicycle (e-bike) for the first time, there is a good chance you have some questions. Well, you have landed in the right place. This Blog is specifically related to the types of electric motors that power e-bikes. The e-Bike industry is rapidly growing due to the increase in consumer interest and the movement towards clean green energy. Electric Bike Motors are much more than “just a motor”.

All e-Bikes are powered by one of three different motor configurations. Although it is possible to have two motors, most e-Bikes don’t. The most common and affordable is rear wheel drive or “Rear Hub Motor”. Hub motors can be “Direct Drive or Geared Drive”. The second type of motor is connected to the crank between the pedals. This is called “Mid Drive” and is rapidly becoming more popular. It is more expensive than Hub but has advantages that make it worth the additional investment. The third configuration is front wheel drive or “Front Hub Motor”. Front Hub e-Bikes are generally conversion kits on a standard bicycle. They are the most affordable, due to the design simplicity and power rating. Front hub motors also have some disadvantages. They tend to have the least torque and produce an unnatural ride. The front motor is pulling at the same time the back wheel is pushing from the rider pedaling. Steering can also a bit challenging and a learning curve.

How e-Bikes are Powered

Torque

The International System of Measurement units (SI units) used for torque is newton-meters or N*m. Even though newton-meters are equal to Joules, since torque isn’t work or energy so all measurements should be expressed in newton-meters… Say What? Joules… Newtons? The only newton I know is a Fig Newton.

OK… relax. I’m right there with you. The point is, if you needed a PhD in Physics to buy and ride an e-Bike, they would not be gaining in popularity as fast as they are. However, if you are that one in a million that really want to get “technical”, the illustration on the right will be of interest to you.

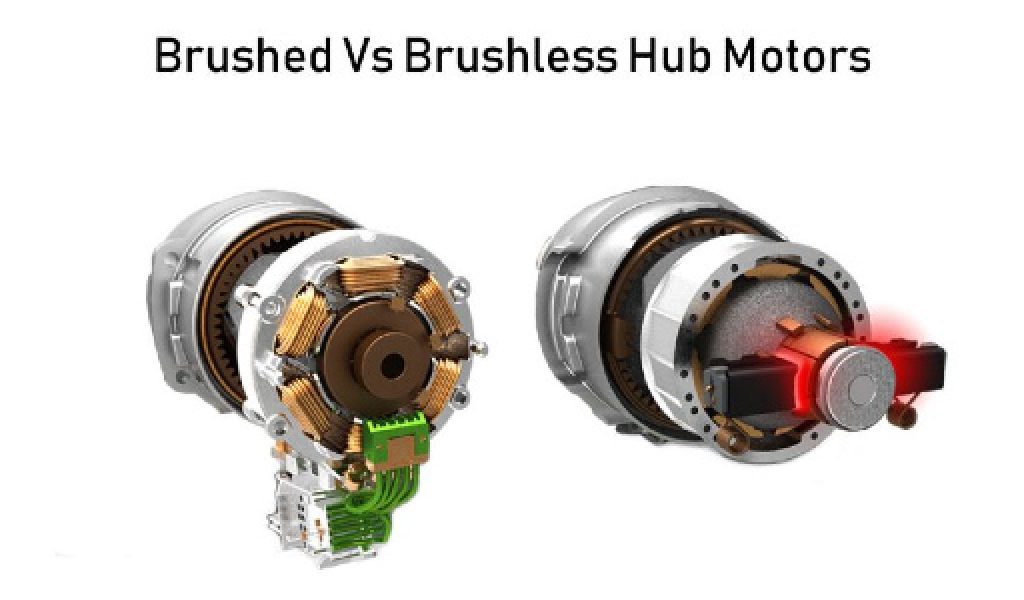

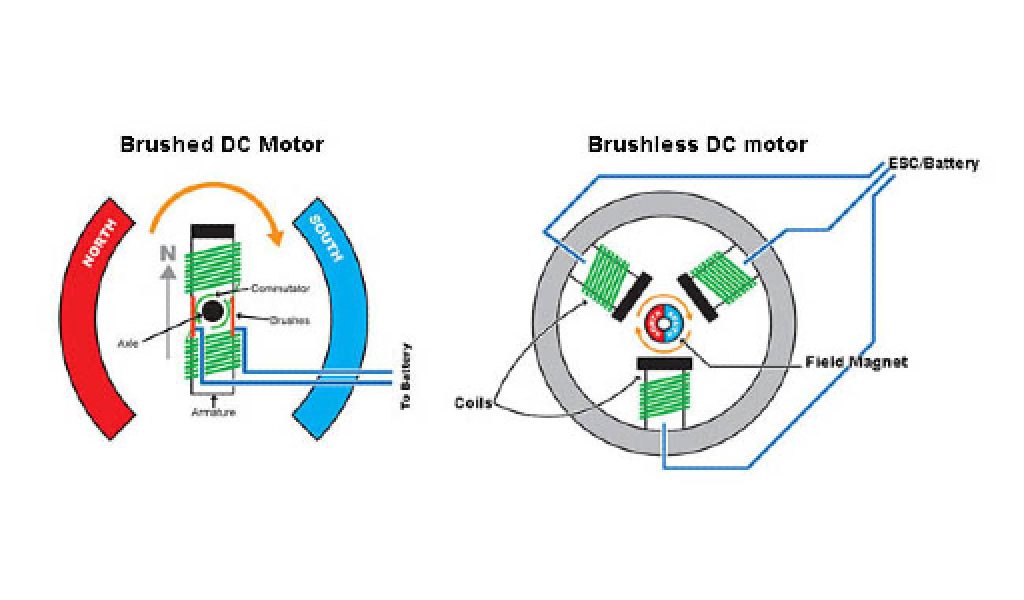

This definition is intended to simply, without a lot of big technical words, explain how e-Bike motors work. Electrical energy is converted into mechanical energy by electric motors. Brushless DC motors, or BLDC motors, are used in e-bikes instead of motors with brushes, which are used in older electric motors to switch the direction of current flow. Brushless motors have been the norm for more than 10 years because brushes made motors less effective and appeared to wear out over time. So what’s the difference? The difference is in the way the motors are designed. Lets take a closer look.

BRUSHED MOTOR: A brushed motor’s brushes are constantly in contact with a moving shaft, causing a lot of friction. This friction, in addition to making noise, produces heat, resulting in wear and tear on the internal components and energy loss due to resistance caused from friction.

BRUSHLESS MOTOR: The rotor in brushless motors is not in contact with anything.

There is less noise and nothing to wear down over time because there is no friction. Furthermore, they are not only more powerful and durable than brushed motors, but they also do not need to have brushes replaced or serviced.

Rear Hub Motors

Direct Drive

The simplest e-bike motors are direct-drive hub motors. The shaft of the motor serves as the rear axle. The hub motor spins around the shaft and thrusting you forward because the shaft is fixed in place. Compared to geared hub motors, direct-drive motors have a larger diameter. Increased leverage and higher torque outputs from larger hub motors allow for sufficient power at lower RPMs. Regenerative braking is a technique used by direct drive e-bikes to produce electrical energy when braking. However, the amount of energy obtained is negligible. A cutoff switch tells the controller to become a generator when you squeeze the brakes. Regenerative braking’s main advantage is that it has adds stopping power on steep downhill grades. Rather than friction, the braking energy is absorbed electronically.

Geared Drive

Unlike direct drive hub motors, geared hub motors have an electric motor within the hub that spins at a much faster speed. The shaft of that motor is connected to a set of planetary gears that attach to the hub, slowing down the rotation of the hub. More torque is produced by this process, but top-end speed is reduced. Since they don’t need as big a motor to produce the same amount of torque on the wheel, geared hub motors have a smaller diameter than direct-drive motors, but the planetary gears make the hubs wider. There is also a freewheel on the motor, which eliminates the possibility of regenerative braking. When current is not being applied from the throttle, geared hub motors coast freely rather than causing a slight drag. As a result, e-Bikes with geared hub motors ride much like conventional bicycles.

Direct drive hub motors can produce a lot of torque and power. This makes them ideal for high-performance e-Bikes. Direct drive motors are typically large and powerful, which adds to the total weight of the bike and reduces range. Since the thermal mass of the motor acts as a heat sink, the extra mass helps the motor avoid overheating. Direct drive hub motors for light duty are usually rated between 250 and 750 watts.

Larger direct drive engines can range from 750 to 1,000 watts.

Compared to direct drive motors, geared hub motors are smaller and lighter. This will help extend the range on a single fully charged battery. They’re also do not have as much power (torque) and have a shorter lifespan. Most geared hub motors have a maximum power rating of 350 watts. Some of the geared drive motors manufactured by Bafang have maximum power rating as from 500 watts up to power rating of 1,000 watts.

By replacing one of the three plastic planetary gears with a metal gear, e-Bike riders have been able to extend the life of the plastic gears within geared hub motors. This helps the metal gear to bear the brunt of the load, preserving the other two plastic gears and extending the hub motor’s useful life. The motor can usually get a little louder as a result of this.

Direct Drive

Geared

The choice between a geared and a direct drive hub motor is normally dictated by two factors: your power and weight needs. You’re pretty much limited to a geared hub motor if you want your electric bicycle to be as light as possible.

The direct drive hub motor is your best choice if you want a powerful e-bike, particularly one with more than 1000 watts of power.

Pros

- the simplest e-bike motor

- the motor shaft is the rear axle

- spins around the shaft

- higher torque outputs, power at low speeds

- motor will be heavier which will make the whole bicycle bulkier

- maximum speed of a gearless hub motor is faster

- better for high-speed high torque off road riding

- battery life is generally shorter, dependent on rider use

- no gears to wear out and cause motor failure

Cons

- more complex because of moving gears that can fail

- motor’s shaft connects to three gears that connect to the hub

- the hub spins at a lower speed than the motor

- smaller in diameter and lighter reducing overall bike weight

- maximum speeds are generally slower than direct drive

- can produce more energy with less electricity

- better for low-speed high-torque traditional cruising around

- battery life can be longer, derailleur gear choice is a factor

Mid-Drive Motors

Mid-drive motors are found between the cranks (pedals) of an e-Bike. Torque is produced by an electric motor that spins a shaft connected to the bikes chain. As a result, rather than adding an extra power source at the rear wheel, the mid-drive motor supplements the pedaling power using the bike’s chain drive system. Since mid-drive motors spin hundreds of times per minute, much faster than you can pedal, the motor’s internal gearing decreases the RPMs at the shaft. This allows the system’s performance to be optimized to an average cadence of about 65 RPM. The motor pack also includes a gear-reduction system. Gear sensors cut the power to the motor when the rider is shifting gears. This prevents the chain from breaking when the bike isn’t in gear. This feature is on all but the most basic mid-drive systems.

Mid-Drive Motors vs Hub Motors

Determining whether you want a hub-driven or a mid-drive e-bike requires weighing your preferences. With that in mind, consider the advantages and disadvantages of each design. Mid-Drive motors use the bike’s current geared drivetrain (derailleur) to take advantage of higher gear reduction for low-speed climbing, mid-drives climb steep hills more quickly than hub-driven e-bikes. When a hub motor isn’t spinning at its peak RPM, the performance disadvantage occurs. The efficiency of a powerful geared hub motor should be comparable to that of a mid-drive motor. Mid-Drive motors offer a more balanced ride because of their location on the bike, in the center between the front and rear wheels. This, combined with the fact that they have a climbing advantage, makes them the preferred motor for mountain e-Bikes.

Pros

- centered position on the bike creates a more balanced ride

- using the bike’s existing gears can climb steep hills more efficiently

- does not affect removing the rear tire in the event of a flat

- can use the energy in your battery more efficiently

- usually lighter and smaller than a hub motor of comparable power watt ratings

Cons

- much more expensive because they contain more mechanical components

- for most riders, there’s no need to pay the extra money

- hub motors are produced in larger volumes and have been around longer

- hub motors require little or no maintenance

In certain situations, there are some efficiency and performance differences. In conclusion, if you expect to find yourself in riding conditions such as steep, long hill climbs, then a mid drive maybe the answer for you. For the average city, commuter, cruiser or the recreational trail rider, a hub motor will do the job. A Hub Motor will save you money on the purchase and maintenance expenses based on normal use over time.

Motor Controllers

Motor controls and batteries are used on e-bikes. The controllers control how much power is sent to the motor. Your input is often used to transfer the appropriate amount of current from the battery to the motor. The experience of how power is used to assist the pedaling is what makes an e-bike an e-bike. A speed or cadence sensor can be used on pedal-assist e-bikes. The speed sensor controls the amount of assistance provided by detecting the rider’s pedaling cadence, or the rate at which the pedals rotate. Torque sensors are often used to calculate or sense how much torque or force is applied to the pedals by the rider. Some e-bikes have throttles that let you use the motor without having to pedal.

There are a few more things you should know about what controls the motor that will in turn effect your riding experience. When to use the throttle and what type of cadence sensor.

What Type of Sensor

Cadence Sensors

e-Bikes use sensors to determine pedal-assist levels based on the riders input. These speed sensors, also called cadence sensors, govern the amount of electric needed to e-assist the rider based on the cadence of the riders pedaling. Sensors are affordable, low-maintenance, and provide a relaxed riding experience that many cyclists appreciate. If you want to go faster, pedal faster, not harder. Increasing your cadence, regardless of how much work you’re putting in, is the simplest way to speed up. On hub-driven e-Bikes, speed sensors are standard.

Torque Sensors

Torque sensors measure how much torque you add to the pedals to calculate the correct amount of motor torque.

You must pedal harder to go faster. The sensation is similar to that of riding a conventional bicycle. Torque sensors are common in mid-drive bikes, especially e-mountain bikes, since they give riders more control over how much e-assist they get.

When To Throttle

Some e-bikes have throttles that allow riders to use e-assist without having to pedal. Whether or not to purchase an e-bike with a throttle or not is a personal choice. Throttles have become useful on hub-driven bikes, particularly if you brake down due to drivetrain failure. There are also some legal issues to keep in mind. Most US States have set laws that act as guide lines that determine what Class the e-Bike falls in. A class 1 e-Bike has only pedal-assist and tops out at 20 mph, a class 2 e-Bike has pedal-assist and a throttle and tops out at 20 mph, and a class 3 e-Bike has pedal-assist that can top out at 28 mph. If you intend on following your regions laws, check before buying an e-Bike that has a throttle.

What is the top speed of an Electric Bike?

The legal top speed in the United States is 28mph in public space. Electronic circuitry will automatically cutoff power to the motor at speeds greater than 28mph. The average speed is between 15mph and 18mph. However, an e-bike can be reconfigured to go well over 35mph for private space use.

Hub-Drive or Mid-Drive? How do I decide?

If you expect to find yourself in situations such as long, steep hill climbs, then a mid drive maybe the answer for you. For the average city, commuter, cruiser or recreational trail rider, a hub motor will be more than enough for you to get from point A to point B and back.

Do Electric Bikes charge the battery as you pedal?

.

If you have a “Mid-Drive” e-bike, the battery will not charge as you pedal or brake. When the rider applies the brakes, electronic circuits convert the motor into a generator, The resistance that is generated creates electrical energy. The energy goes back into the battery. This is called regenerative braking. The amount of energy created depends of riding and breaking conditions. The primary benefit is additional braking coming down steep grades.

How far can an e-Bike travel?

.

The range of an e-Bike varies from 20 to 60 miles. The distance you travel on a single charge depends on a number of factors. Your body weight, the weight of any cargo you might be caring, the type of terrain you are riding on, the grade of any hills and are you riding with or against the wind. How much you pedal and which power setting / mode you use also affect range.

At the End of The Day...

If a manufacturer lists an e-bike battery’s voltage and continuous amperage from the motors controller, you can get an idea of how much full power you’ll actually feel. This is a more accurate predictor than the motor’s ranking. Torque, on the other hand, is less arbitrary. If an e-Bike’s peak or sustained torque is mentioned in newton meters, consider that data to be accurate and correct. Percentages of support indicate how much assistance the motor is providing at a given e-assist stage.

You might also like...

Year Round Riding – eBiking in Different Seasons: Tips Embark on an E-Bike Adventure Through …

Best Biking Cities in the USA for Electric Bicycles Every year on June 3rd, cycling …

More than This… Less than That… e-Bike… Budget, Mid-Range or Premium? You may be curious …

People one said that buggies would always be pulled by horses and bicycles would always be pushed by your legs. Well, that was 100 years ago and times have. EV Pedal Power is here to help you find that electric bicycle that fits your needs in the 21st century. With so many to choose from, our links are here to point you in the right direction.

EV Pedal Power participates in various affiliate marketing programs. We may get paid commissions on chosen products purchased through our links to merchant sites.

Recent Comments